JustynaDuan@hytbearings.com

获取短信验证码

2021-04-15

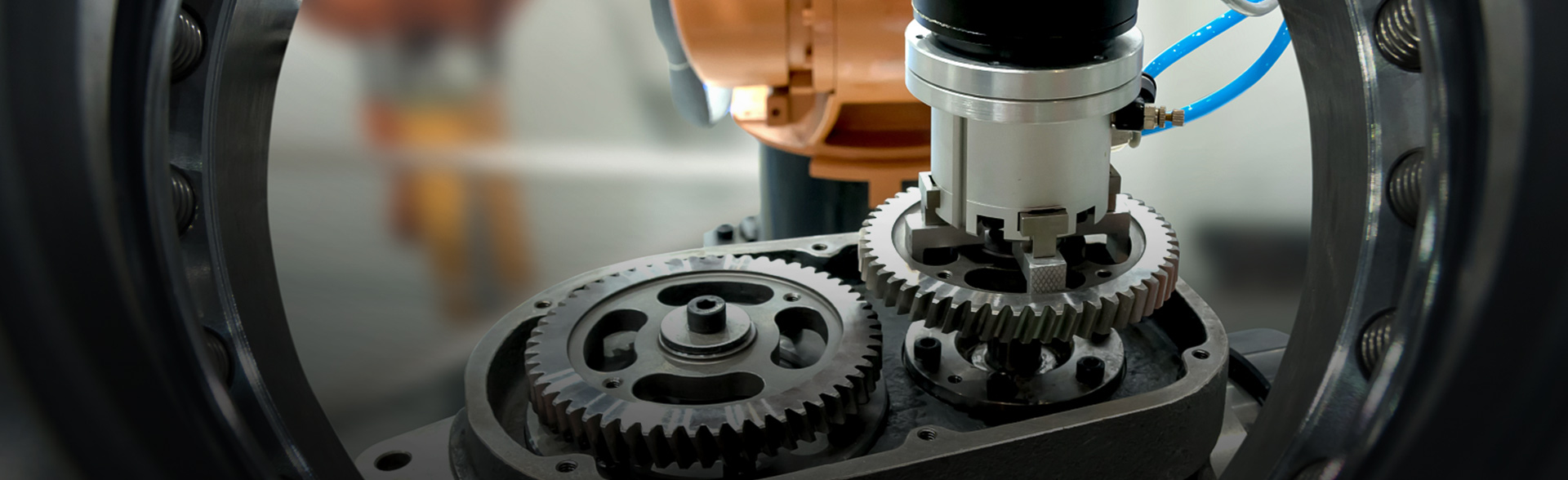

In order to meet the ever-increasing demand for steel for construction, my country's metallurgical industry has put forward stricter requirements on the matching bearings due to the special nature of the high-speed wire rolling mill. The working characteristics, structural forms, design points and manufacturing keys of high-speed wire rod rolling mill bearings are briefly introduced. The most notable feature of the high-speed wire rod production line is the high reliability of the continuous operation of the rolling mill. Due to the high unit output of the high-speed wire rod production line, it is required that the bearings, which are the key components of the rolling mill, have higher reliability than the ordinary rolling mill bearings within the specified inspection cycle. If a bearing failure will cause the entire production line to stop production, this is something that the manufacturer cannot tolerate. Therefore, when designing and manufacturing high-speed wire rolling mill bearings, the reliability of continuous operation under high-speed operating conditions should be ensured. Wear-resistant high-speed wire rolling mill bearings have strong wear resistance and can adapt to high-speed rotating work occasions. The bearing fatigue life of high-speed wire rolling mill should be long. The bearing design method firstly adjusts the main parameters appropriately according to the operating conditions, service life, failure status and user requirements of the bearings on each line, so that the design can achieve a relatively satisfactory effect.