JustynaDuan@hytbearings.com

获取短信验证码

2013-03-16

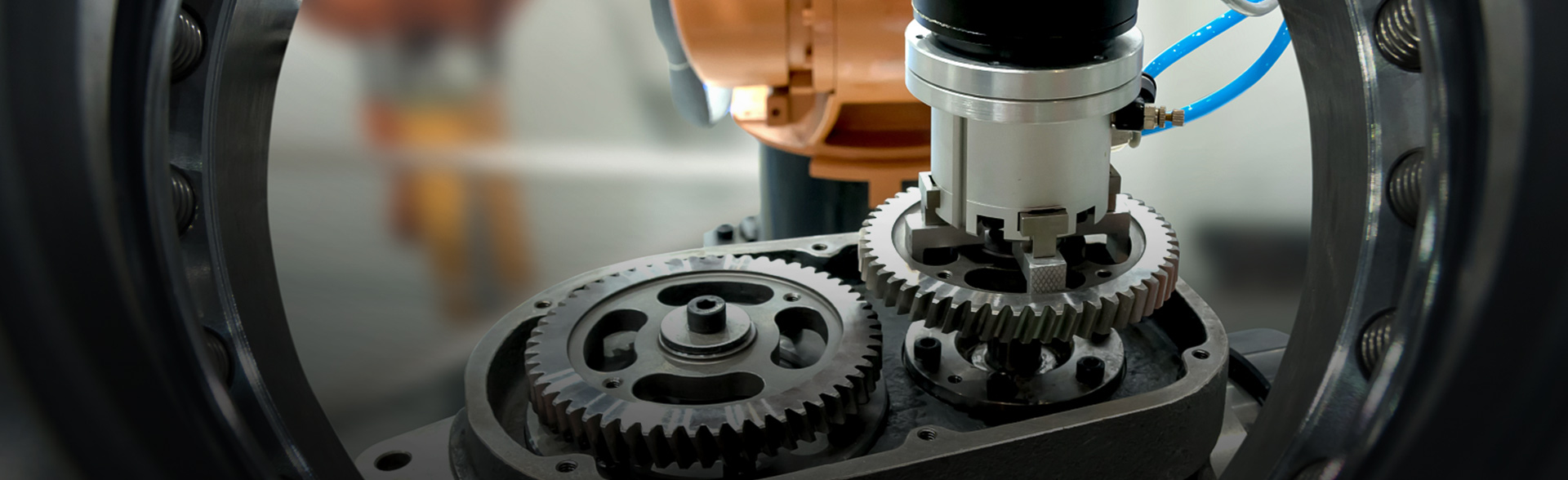

The proper selection of materials is still a factor that must be considered in bearing failure analysis. The main task of double row angular contact ball bearing failure analysis is to find out the main factors causing bearing failure based on a large number of background materials, analysis data and failure modes, so as to propose improvement measures to extend the service life of the bearing and avoid Sudden early failure of the bearing occurred. Installation conditions are one of the most important factors in the use of factors. Bearings often change due to improper installation, resulting in changes in the stress state between the various parts of the complete set of bearings. Double row angular contact ball bearings operate under abnormal conditions and fail prematurely. According to the technical requirements for bearing installation, use, maintenance, and maintenance, monitor and inspect the load, speed, working temperature, vibration, noise and lubrication conditions of the bearing in operation, find the cause immediately, and make adjustments when the abnormality is found. Back to normal.

1. Ensure the minimum installation interference of double row angular contact ball bearing inner ring;

2. Guarantee the minimum oil film thickness criterion;

3. Maximum mechanical load and shock load criteria;

4. Criteria for relevant conditions (bearing seat, shaft stiffness, sealing, etc.).

5. Maximum heat load (absolute humidity, temperature) criteria.

Huayingte angular contact ball bearing will be your best guarantee to ensure the efficient operation of your machine.